- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

The cost of central air conditioning has become an increasing financial burden on building operating budgets. Magnified by the soaring cost of energy, the problem can no longer be ignored. Although progress has been made in eliminating waste and optimized use of conditioned air, more areas of cost cutting should be explored.

In the search of ways to reduce building operating cost and energy consumption in the new US Department of Labor Building, a simple method of improving heat transfer was applied: automatic tube brushing.

The application of this technology allowed a reduction from 0.89 kW/Ton to 0.64 kW/Ton on their three 1500 Tons and one 1000 Tons centrifugal chillers. The initiative earned Joseph, buildings and facility manager, a Presidential letter from the White House, citing him for contributing to energy consumption and more economic management: “Mr. Petritsch, your actions demonstrate vision for service and excellence and it is comforting to know we have such highly committed professionals like you and your team in this country.”

To compensate for fouling of heat transfer surfaces in refrigeration machines and resulting drop in capacity, designers have traditionally provided extra machine capacity and manufacturers have accepted an allowance for fouling. Although this permits a longer interval between cleaning, the burden of operating fouled machines results in (often) undetected excess expenditure of energy. The fouling buildup requires the compressor to work harder to drive the rejected heat into the cooling water. This process is in many cases tolerated until the chiller can no longer produce the required cooling capacity, which then triggers an interruption for mechanical or chemical cleaning.

The system that Joseph purchased and installed consists of two baskets and one brush for each condenser tube and a flow reversal valve. A basket is mounted on each end of the tube to house the brush at the downstream end of the tube where it permits full flow without measurable pressure drop. The brush is regularly propelled through the tube by reversing the flow direction of the condenser water, accomplished by the flow reversal valve that is incorporated in the cooling water piping system. Each tube is brushed twice during each cleaning cycle. With negligible wear, the service life of the brushes reaches 5 years easily.

Depending on existing cleaning and water treatment regime, energy savings range from 10-35% with minimal operator attention required because of the systems automatic features. In practice this means a payback of less than one year.

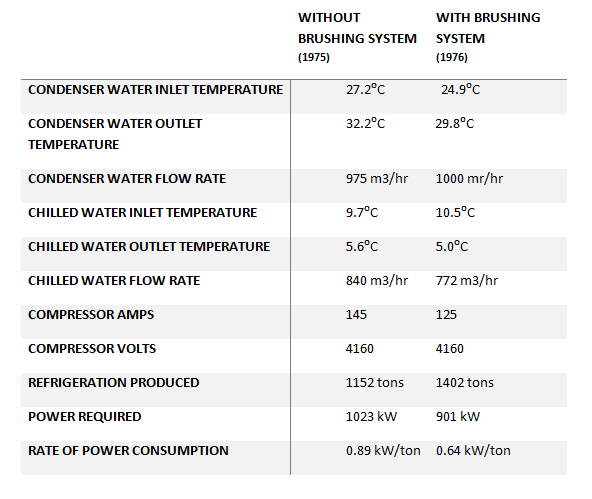

Before installation of the tube cleaning system, at the beginning of the cooling season, the condensers were cleaned by circulating acid solution over the tubes to soften up the heavy scaling buildup, after which tubes were flushed out with the use of a jiffy gun. Precision test instrumentation was used to compare operating data prior to and after installation of the brush cleaning system. The acquired performance data are presented in the table below. Comparative operating cost are calculated by extending power consumption rates with contemplated machine loading and existing electricity rates.

The result: US$ 82,080 per year with brush cleaning compared to US$ 114,142 without the system. The difference of US$ 32,062 yearly due to energy savings alone does not include additional savings due to elimination of periodical manual condenser tube cleaning. This substantiated the one-year payout of the capital investment of the system.

Assuming 3000 running hours per year with an average load of 75% and an electricity rate of US$ 0.038/kW the results are as follows:

| Without brushes: | 1500 tons x 75% x 0.89 kW/ton x 3000 hrs/year x $ 0.038 | = $ 114,142 / year |

| With brushes: | 1500 tons x 75% x 0.64 kW/ton x 3000 hrs/year x $ 0.038 | = $ 82,060 / year |

| Savings: | = $ 32,062 / year |

Note: Read the original article here. It’s a faded PDF from the publication in 1976, amid the 1970’s energy crisis when Jimmy Carter was elected president. With today’s need to minimize energy consumption in relation to global warming, it is remarkable how relevant this 40-years old case study still is today.