- Main

- Chiller Efficiency

- Auto Tube Brushing

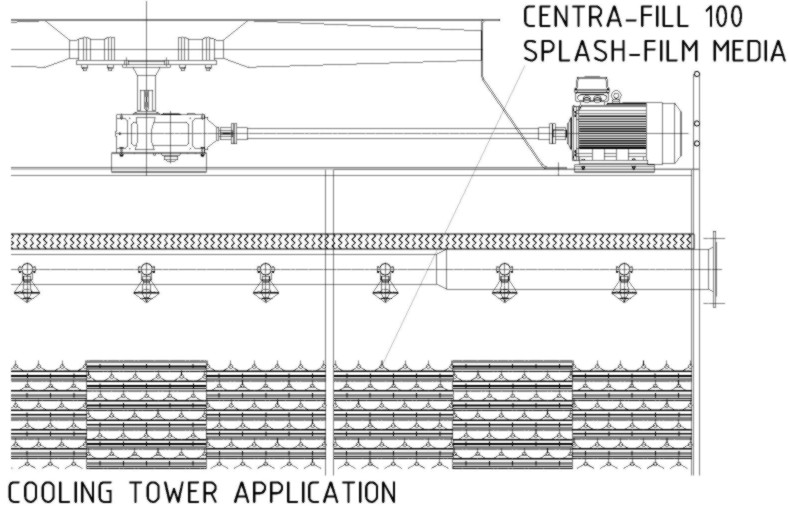

- Cooling towers

- Motorless Turbine

- Contact Us

The CentraFill® cooling tower fills consists of predetermined layers of triangle corrugated profiles. The triangle bars are in cross-section towards each other in the tower structure.