- Main

- Chiller Efficiency

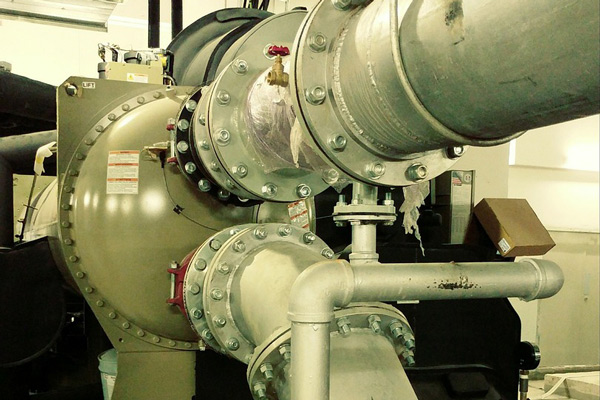

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

Energy Efficiency in Commercial Buildings is a challenge for the coming decades, particularly improving energy efficiency in existing buildings.

Responsible building operators push improving building energy efficiency to the top of their agenda.

Reducing energy consumption in commercial buildings starts with common sense, and a lot of work can be done by your own team before calling in the support of a specialized consultant.

Start the decarbonization of your building with a critical analysis of possible energy-saving measures. Two separate main workstreams, focusing on the building side respectively the cooling plant side, can generate easy-to-implement ideas to make an immediate difference. ENERGY SAVING IN COMMERCIAL BUILDINGS

When the building heats up, we need cooling.

How can we minimize the build-up of heat (minimize the need for cooling)?

How do we maximize the efficiency of heat removal from the building through the chiller plant room (Chillers and Cooling Towers)?

WATCO teamed up with ClimaCheck to bring you a solution for energy saving in the chiller plant room. This chiller monitoring tool is unique, one in its kind, easy to implement, and affordable. It will help you shave percentages of your overall energy consumption through the optimization of the highest electricity users in your building: the Chillers.

In a (sub) tropical environment electricity consumption largely takes place in the chiller plant room: the chillers may take over 50% of the total electricity consumption in the building. 95% of commercial chillers waste between 5-30% of their energy due to inefficiencies that can easily be avoided.

When finding ways to reduce energy consumption in buildings, the most logical step is to start looking at those chiller inefficiencies immediately.

The chiller is an expensive and complex piece of equipment and chiller optimization and adjustment should be an ongoing process when reducing HVAC energy consumption in buildings.

Think of your chiller as a Formula-1 racing car. F1-Team captains (building managers) and F1-drivers (operators) depend on continuous data to achieve maximum performance. No F1 teams wins the championship without using the available data to the fullest.

Why chiller monitoring is so crucial? – Watch the video “The importance of monitoring your Chiller” below.

Contrary to what you may expect, your BMS (Building Management System) normally does not provide data on the efficiency realized per individual chiller. Chiller COP is not suitable to use as KPI as the COP highly depends on the running conditions of your equipment. Energy-saving functionalities in the BMS allow for optimal planning and use of various equipment in the chiller plant (sequencing of chillers, pumps, and cooling towers) but do not take data on the energy efficiency of the (sub) systems in the chiller.

The ClimaCheck chiller monitor provides the data for an ongoing improvement process to achieve Energy Efficiency in Commercial Buildings through:

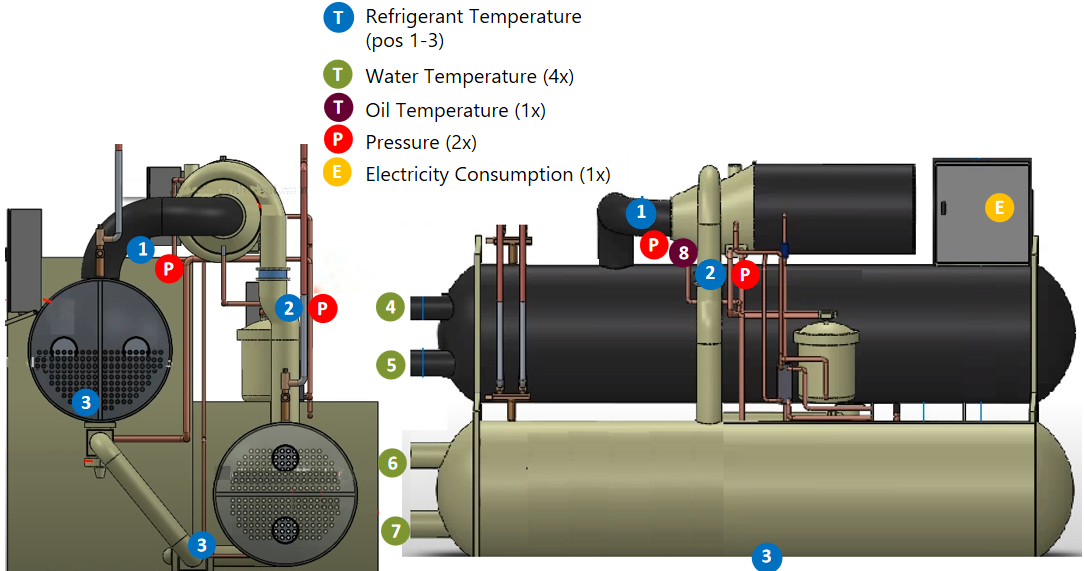

The ClimaCheck system takes data via the internal method (measurement of the refrigeration cycle), and breaks down the overall efficiency to efficiencies of the 4 subsystems of the chiller.

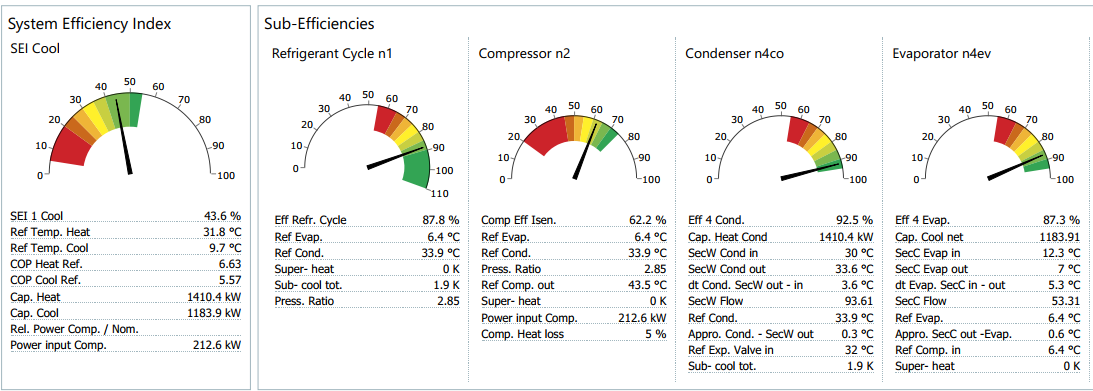

The uniformly applicable System Efficiency Index (SEI) is calculated as realized COP as % of ideal COP (at prevailing running conditions). SEI lets you compare all chillers at any time interval and is the ideal tool for KPI settings for your operator and maintenance teams.

A 2-circuit water-cooled chiller (300 RT) was monitored. Although performing well in terms of cooling delivered, analysis brought up problems with:

A series of simple adjustments on the Chiller sequencing in combination with smart usage of the chilled water storage and the introduction of a condenser cleaning regime allow for 30% energy saving on the chiller.

The monetary value of the avoidable waste:

A 30-minute monitoring session on a chiller pointed out problems with compressor efficiency and oil cooling that dropped the System Efficiency 16% below its expected value. The owner called on the chiller manufacturer and the problems got remedied Free of Charge.

The monetary value of the avoidable waste:

Start by doing what is necessary, then do what is possible and suddenly you are doing the impossible.