- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

Chillers are high energy consumers and over 95% of the chillers waste 5-30% of the electricity on avoidable inefficiencies. Performance monitoring is the first step in chiller efficiency optimization.

Reduce your Chiller operating costs through optimization of energy efficiency, increased plant reliability and reduced equipment wear with this DENA endorsed solution (German Energy Agency) from our partners ClimaCheck AB in Sweden.

Identify saving opportunities and validate the saving measures taken to realize optimal Energy Efficiency.

Identify emerging problems before they cause system failure and increase your energy bills with ClimaCheck.

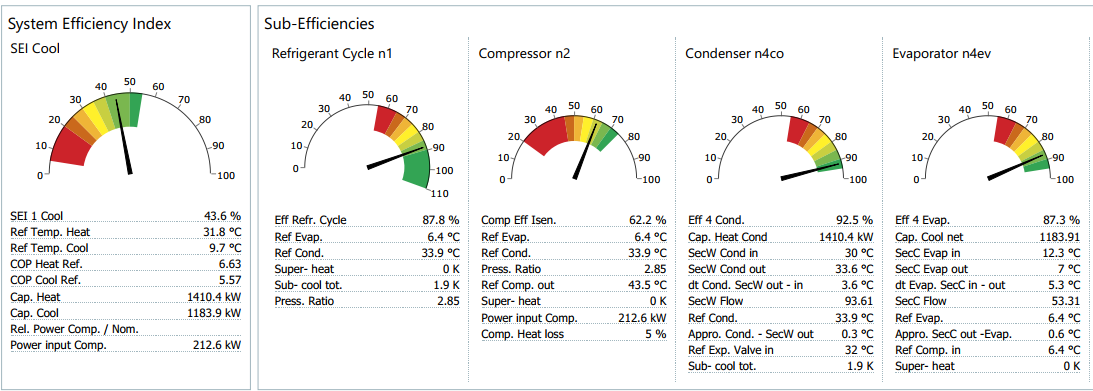

Use the SEI and the efficiencies of the sub-systems to flag deviations from optimal performance and allow for benchmarking across your chillers.

The chiller is an expensive, sensitive, and complicated piece of equipment and its performance impacts people and processes. Chiller failure can have serious consequences. With real-time data, you can be confident in the fact that the chiller functions optimally :

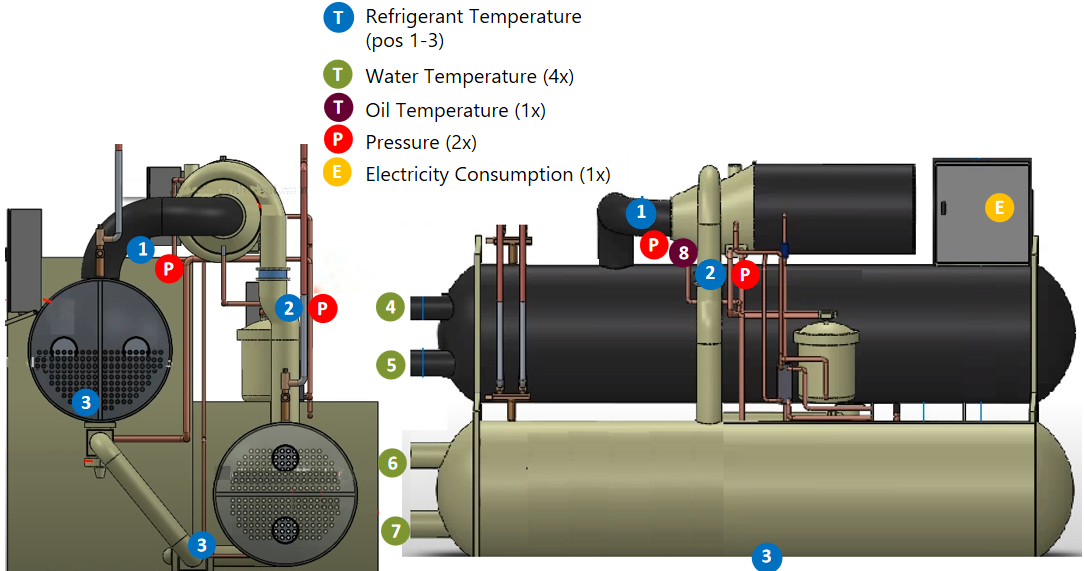

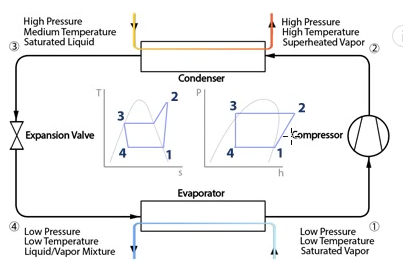

The ClimaCheck system takes data via the internal method (measurement of the refrigeration cycle) and breaks down the overall efficiency to efficiencies of the 4 subsystems of the chiller. This method is highly accurate and allows you to:

The uniformly applicable System Efficiency Index (SEI) is calculated as realized COP as % of the Carnot COP (at prevailing running conditions). The SEI lets you compare all chillers at any time interval.

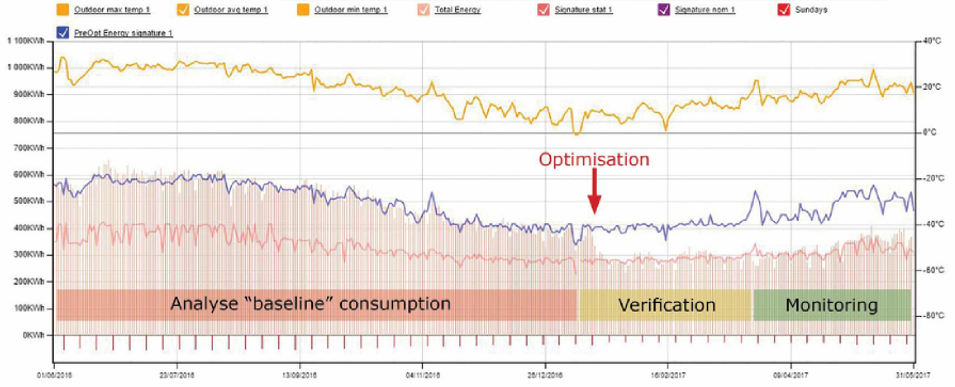

The ClimaCheck chiller monitor provides the data for an ongoing improvement process that allows you to:

The system can be installed within a day with immediate access to your data.

| Item | Issue |

| Condenser | Fouling and Corrosion |

| Refrigerant | Shortage or overcharge |

| Flow balancing | Too high or low on chilled or cooling water |

| Compressor | Wear and tear, damage |

| Controls | Not properly commissioned |

| Components | Changed or upgraded without proper review |

| VFD | Essential for capacity control but not correctly set up or used |

A 2-circuit water-cooled chiller (300 RT) was monitored. Although performing well in terms of cooling delivered, the analysis leads to the following recommendations:

A series of simple adjustments on the Chiller sequencing in combination with smart usage of the chilled water storage and the introduction of a condenser cleaning regime allow for 30% energy saving on the chiller.

A 30-minute monitoring session on a chiller pointed out problems with compressor efficiency and oil cooling that dropped the System Efficiency 16% below its expected value. The owner called on the chiller manufacturer and the problems got remedied Free of Charge.