- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

The transformative impact of Automatic On-line Tube Cleaning Systems for Heat Exchangers and Chiller Condensers in both industrial and comfort cooling (HVAC) applications is stunning. Online cleaning technology have demonstrated remarkable effectiveness in enhancing efficiency and conserving energy, by keeping the cooling water tubes clean from fouling to facilitate optimum heat transfer. Uncover the multitude of benefits and advantages of Automatic Tube Cleaning with the Eqobrush Tube Brushing system to improve Chiller COP, ensuring a high ROI and retrofittable to existing installations.

James E. Piper observes in his Industry Authority handbook: Operations and Maintenance Manual for Energy Management:

QUOTE

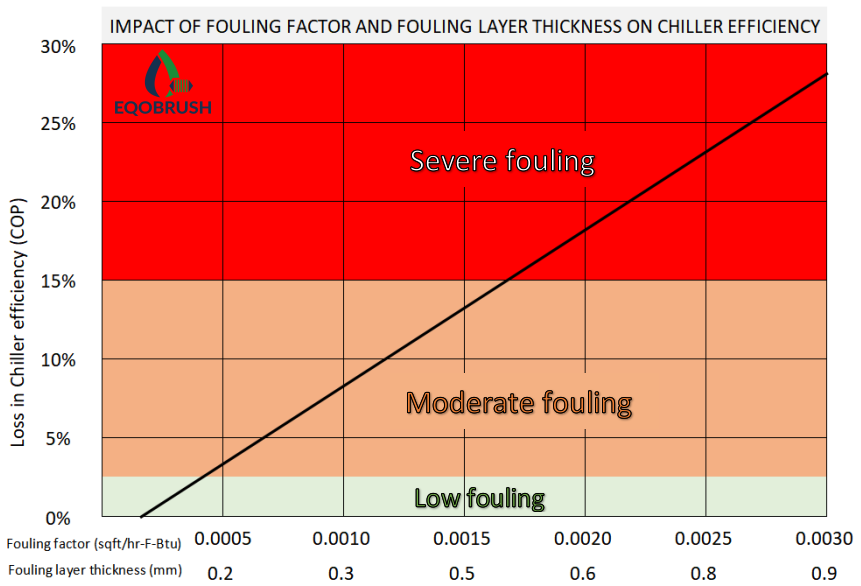

For example, a layer of slime deposits only one one-hundredth of an inch thick (0.01” = 0.3 mm) on a chiller’s condenser tubes raises the fouling factor by nearly 0.001 and causes the chiller to use approximately 10% more energy to produce the same amount of cooling.

UNQUOTE

The Chiller COP (Coefficient of Performance) is defined as:

COP = Net refrigeration effect (kW) / Heat of Work (Compressor electricity use)

Plotting chiller operation data in the tool in the interactive p-h diagram (courtesy of TLK-Energy.de) demonstrates a loss in COP (loss in efficiency) of over 3.5% for each °C in condenser temperature.

If we assume that the heat load of the chiller remains unchanged (and the cooling water temperature remains unchanged), the loss in heat transfer effectiveness will eventually lead to an increase in condenser temperature.

The p-h diagrams demonstrate a negative impact of 7% on COP via a mere 2°C increase in condenser temperature that is caused by a minimal layer of fouling.