- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

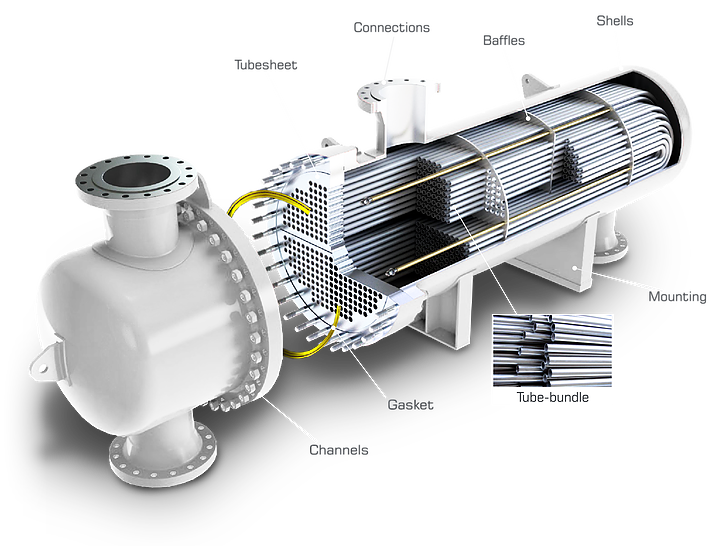

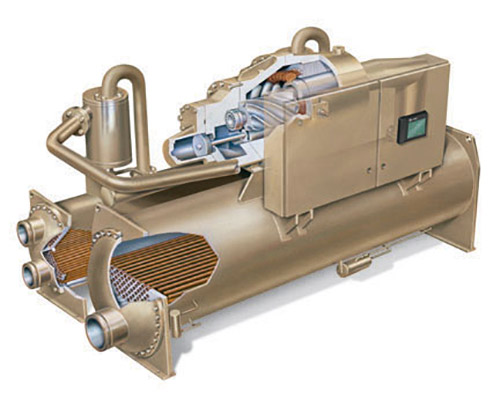

Automatic Brush Tube Cleaning System for Shell and Tube Heat Exchangers, Chiller and Steam Condensers, helps to prevent fouling and scaling of the tubes and to maintain the effectiveness and efficiency of industries and factories power generations without interruption of operations.

System Components | Principle of Operation | Installation Process | Start-up | Maintenance | When Not In Use

The cavemen started brushing their teeth regularly once they found out that “fresh” build-up is easy to remove, as opposed to leaving it untouched and allow scaling. That’s exactly what the tubes of your heat exchanger or condenser need: regular brushing to clean any build-up before scaling sets in.

Eqobrush – Automatic Brush Tube Cleaning System (ATCS) accomplishes exactly that during normal operation of your system. You’re assured that those tubes are kept as pristine as gun barrels, without interruption of operations.

Standard brushes are made from PE caps with Stainless Steel wires and nylon bristles for application in water with temperatures up to 60 ᴼC.

The cleaning function within circular tubes requires a water flow velocity of a minimum of 0.6 m/s at a pressure drop of 0.06 bar. For elliptic tubes, the velocity should exceed 1.0 m/s.

PE baskets are easily removable (and re-usable) from the socket when necessary during inspection or brush replacement.

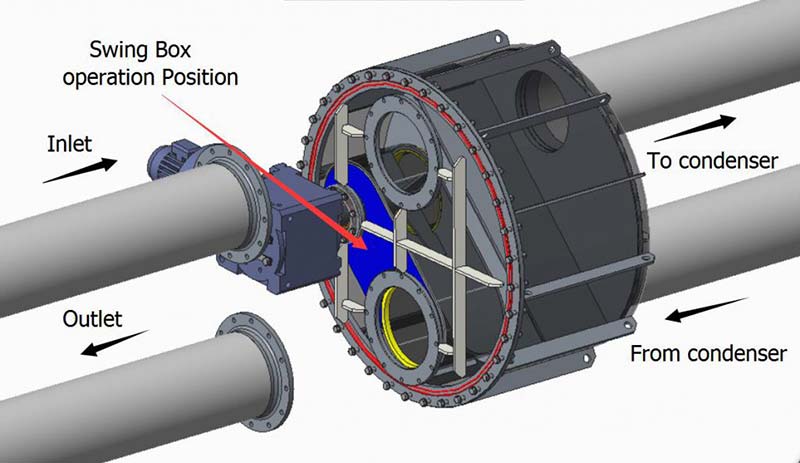

The special reversing valves are designed in the nominal size from 80 mm to 600 mm for nominal flow rates from 50 m³/h to 3000 m³/h.

The standard operational pressure is 6 bar and a cooling water temperature with a maximum of 50°C. In accordance with the actual operating conditions and water quality, the units will be manufactured from construction steel inclusive coating (standard design) or from stainless steel.

Materials and valve designs for different piping layouts are variable.

Compact multi-functional actuator with end position switches and torque control in IP55 housing. Manual emergency operation possible.

Pneumatic actuators or Electric actuators with fail-safe spring return are optional.

The IP55-control panel carries the components required for the automatic operation.

The EQOBRUSH system operates completely independently and does not interfere with other processes. The switchboard therefore does not need to be connected to the overall process control system.

For systems with multiple heat exchangers or chillers we can offer additional options in terms of control and monitoring.

The brush cleaning system consists of two catch baskets and one nylon brush for each heat exchanger tube. Both baskets are permanently fitted to the pipe ends and serve to accept the brushes. By reversing the direction of the cooling water flow, the brush is pressed through the tube and at the other end it is accepted by the basket. When the cooling water stream is diverted again in the normal direction, also the brush will return into the catch basket located at the delivery end. The inner walls of the tubes thus being cleaned now eradicating any fouling or scaling.

The reversal of the water flow direction occurs by means of a reversing valve which can be set to any desired cycle via an electric actuator and control box. The automatic valves of the Eqobrush Automatic Cleaning System reverses the water flow in the heat exchanger every few hours (every 4 to 6 hours) for 30 seconds. Pressure loss is avoided as once the reversion is done and the brushes are positioned in the baskets. This cleaning interval is fixed by our engineers according to the operating conditions and degree of contamination of the cooling medium, but depending on seasons or other influences it may also be changed by the operating personnel.

The cleaning action of the brush makes it possible to remove loose, gelatinous deposits from the internal surface of the tube without any restriction. The hard deposits, tending to adhere more strongly, cannot even get the opportunity to form. Moreover, sludge accumulations or other contamination are precluded, which allows to achieve top performance at all times. There’ll be no more interruptions of operations for mechanical or chemical cleaning.

The brushes, sockets and baskets cleaning cloth, cement, paper cups and application brushes are all provided with the system components. The cleaning solvent needs to be supplied by the owner.

The bottom or back side of the valve (the side that connects to heat exchanger/condenser) can be installed in the pipe work without extra precautions, while the top or front side of the valve (at the cover flange where actuator is to be installed) the piping MUST BE INSTALLED WITHOUT STRESS OR ANY FORCES ON THE VALVE BODY. We recommend rubber compensators in the piping of valve. The compensators supplied should be installed on the actuator (cooling tower) side of the valve

After actuator and position indicator are properly mounted and all wirings are connected according to the diagram, adjust position indicator which controls the initial alignment position of valve inlet/outlet holes and swing box hole of the valve.

PLC will automatically activate every 4 hours to complete a cleaning cycle. It is programmed to record the number of automatic cycles completed (downloadable to PC with specific software)

To start up the water system follow the instructions from the chiller / heat exchanger. Make sure the valve and flange connections do not leak and that there are no air pockets in the pipe work. (Install deaeration valves where necessary).

Once the system pump(s) is running for a while, the first cleaning cycles can be activated manually. Monitor the valve behavior during operation and confirm that the swing box runs smoothly. If not, there may still be air pockets in the system. Let the pumps run for a while till all air pockets are filled.

Once the power is activated and the system runs smoothly, every 4 hours there will be an automatic cleaning cycle. The time of the cycle is stored in the PLC history.

The system is maintenance free and runs 1 to 2 years without any attention. Every 2 to 5 years the heat exchanger heads should be opened to check the condition of the pipes, brushes and baskets. Replace internal components if required.

The actual running time of the actuator is quite limited: +/‐ 2 minutes a day or +/‐12 hours per year. An oil replacement in the actuator is advised every 2 years depending on the ambient conditions of the valve/actuator set. Contact WATCO for more details.

During periods when Heat Exchanger or Condenser is not in use we recommend to

Automatic On-line Brush Tube Cleaning Systems for Heat Exchangers and Chiller Condensers have proven their effectiveness on efficiency and energy saving in industry and comfort cooling (HVAC).

Learn more about the benefits and advantages.