- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

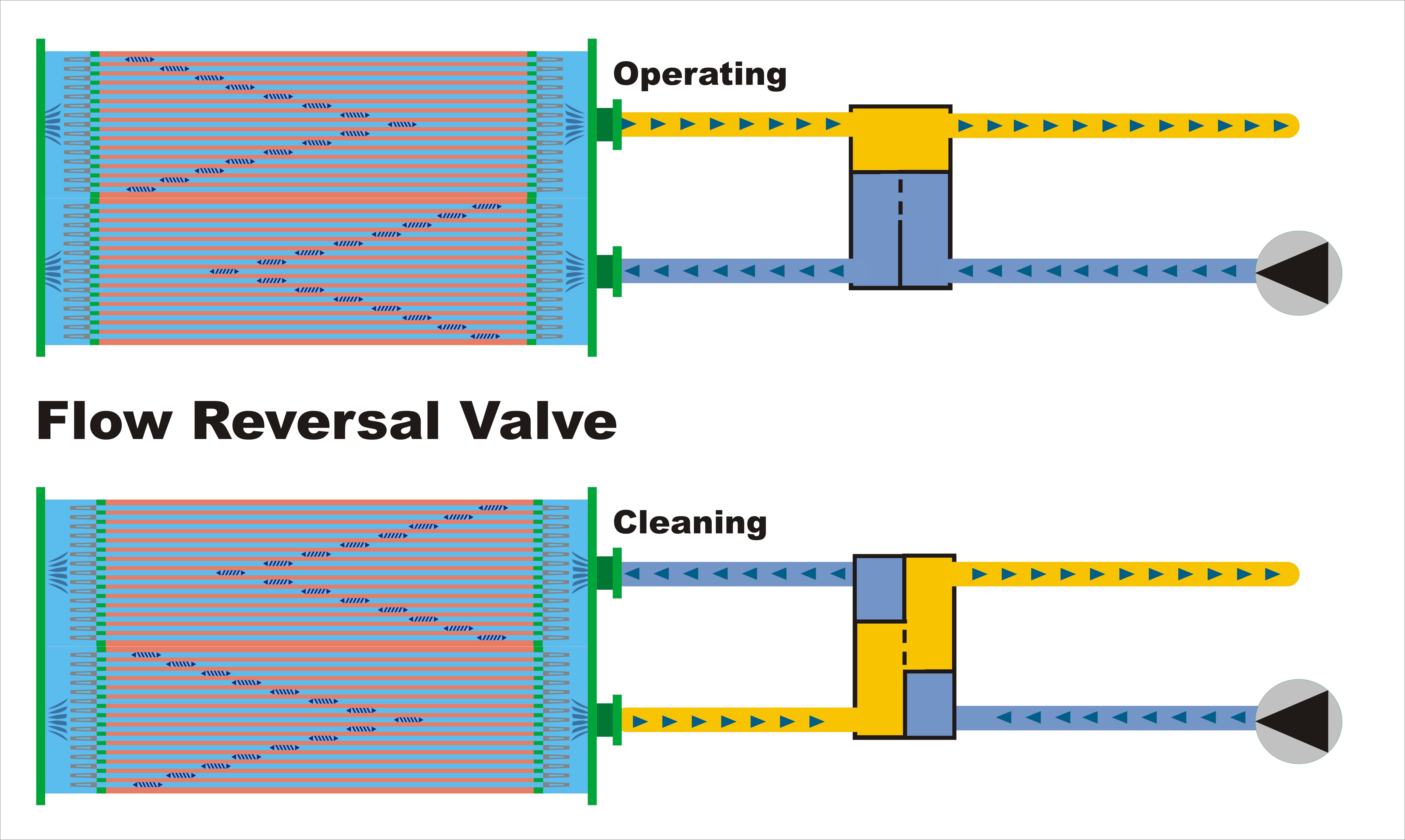

Backflushing is advantageous for heat exchangers as it dislodges accumulated debris, fouling, and scaling from the tubes, ensuring optimal heat transfer efficiency. This process helps maintain equipment performance, extends operational lifespan, reduces maintenance costs, and ensures consistent and reliable heat exchange capabilities.

Eqobrush automatic brush tube cleaning system prevents fouling or scaling in the tubes of heat exchangers, chiller condensers or steam condensers by brushing the cooling water tubes inner walls regularly without interrupting operations. Small brushes travel through the tubes propelled by the water flow that is reversed for a short time at set intervals by the Flow Reversal Valve.

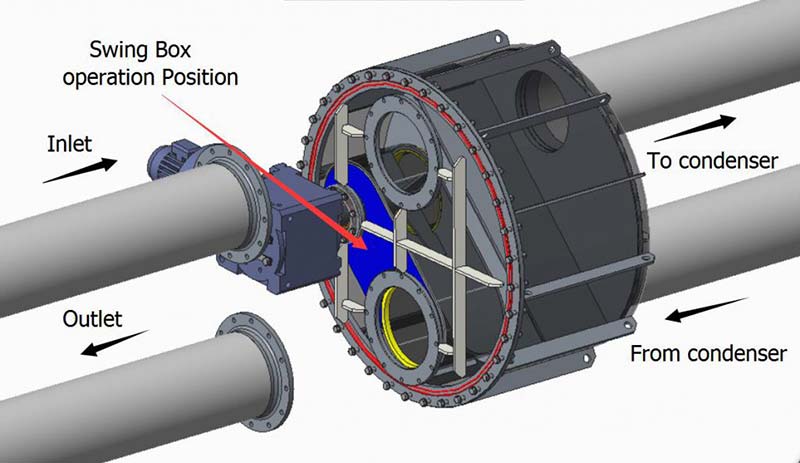

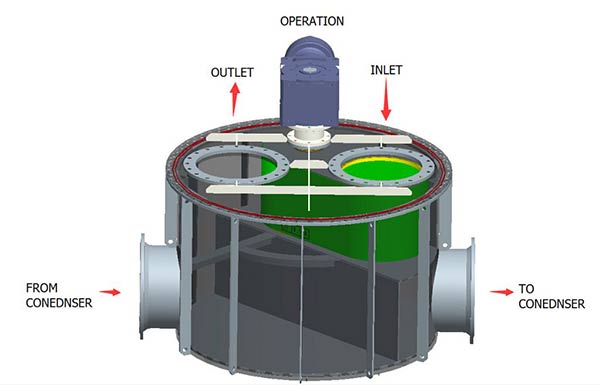

Eqobrush designed the Swing Box. This unique Flow Reversal Valve approach, shaped by decades of experience, tackles common issues. It offers enhanced reliability and efficiency compared to standard valves, drawing on refined engineering principles and practical insights. Its innovation aims to optimize performance and address challenges in flow control mechanisms.

The Flow Reversal Valve facilitates flow direction changes within heat exchanger and chiller condenser tubes while preserving flow direction to the cooling tower. This enables brushes within the unit to traverse the tubes, removing newly settled fouling and scaling. Typically, flow reversal occurs approximately 6 times daily, each instance lasting less than one minute without affecting normal operation. Activation can be manual or automatic based on programmed schedules tailored to operational needs. This periodic reversal ensures efficient heat exchange and optimal system performance by preventing buildup and maintaining tube cleanliness throughout regular chiller operations.

In accordance with the actual operation conditions and water quality, the units will be manufactured of:

– construction steel inclusive coating (standard design)

– stainless steel

Automatic On-line Brush Tube Cleaning Systems for Heat Exchangers and Chiller Condensers have proven their effectiveness on efficiency and energy saving in industry and comfort cooling (HVAC).

Learn more about the benefits and advantages.