- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

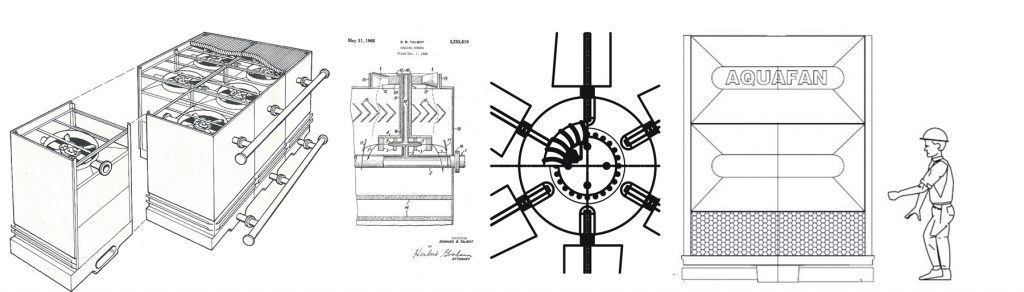

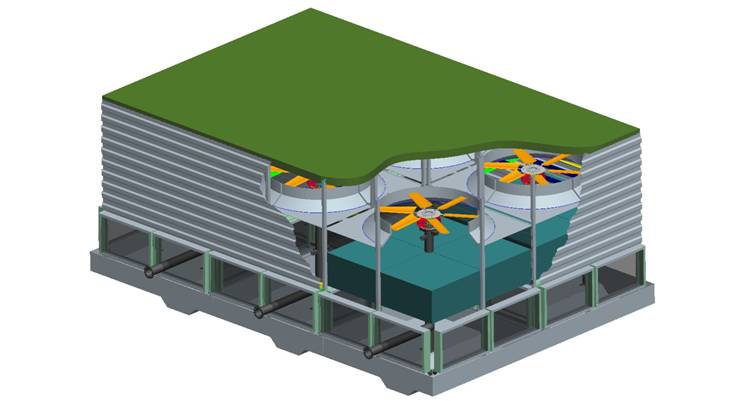

In Aquafan turbine powered cooling towers we convert water pressure into fan movement. The Aquafan cells’ fans are controlled via the system pump’s water pressure. The pumps are selected to generate sufficient pressure to drive the fan. It’s simple and efficient and saves energy and maintenance.

For applications with a limited residual pressure, we can select a hybrid cooling tower design with a motor-assisted fan to achieve the required fan rotation to deliver the cooling job.

Conventional forced draft cooling towers require an electric motor to drive the fan to create the airflow in the tower. AQUAFAN cooling towers utilize the system’s water pressure to drive a water turbine. Consequently, energy savings of 30% and more are achievable.

Unscheduled down time of water cooling towers involves substantial costs. Repair and maintenance of mechanical components (electric motor, drive shafts and gearboxes) can be minimized, as AQUAFAN turbines do not use these components and are therefore very reliable in their operation.

The AQUAFAN cooling tower design has an integrated fan-turbine combination completely made from corrosion free materials that are hidden below the drift eliminators. The box-shaped design of the modules can be perfectly integrated into the architectural design.