- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

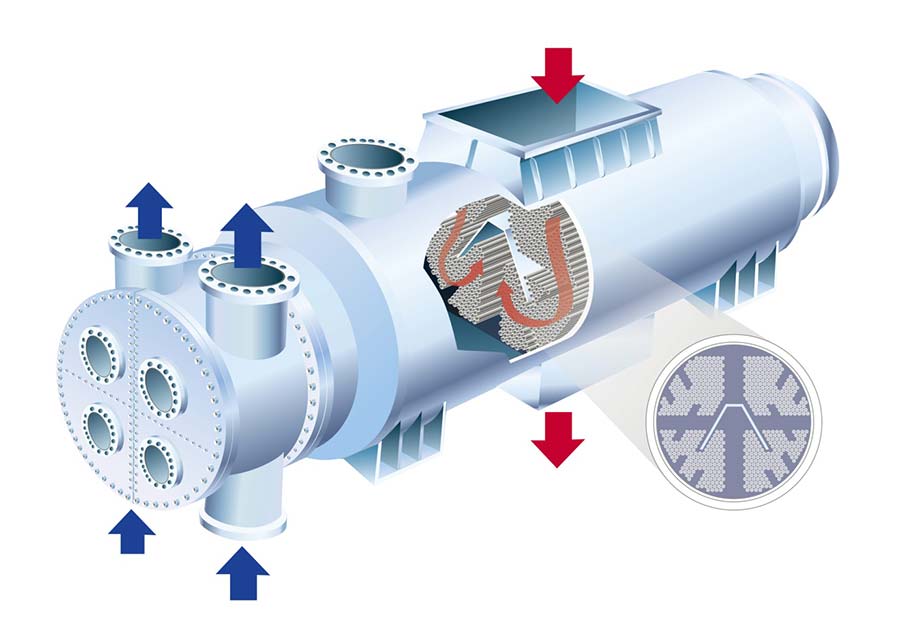

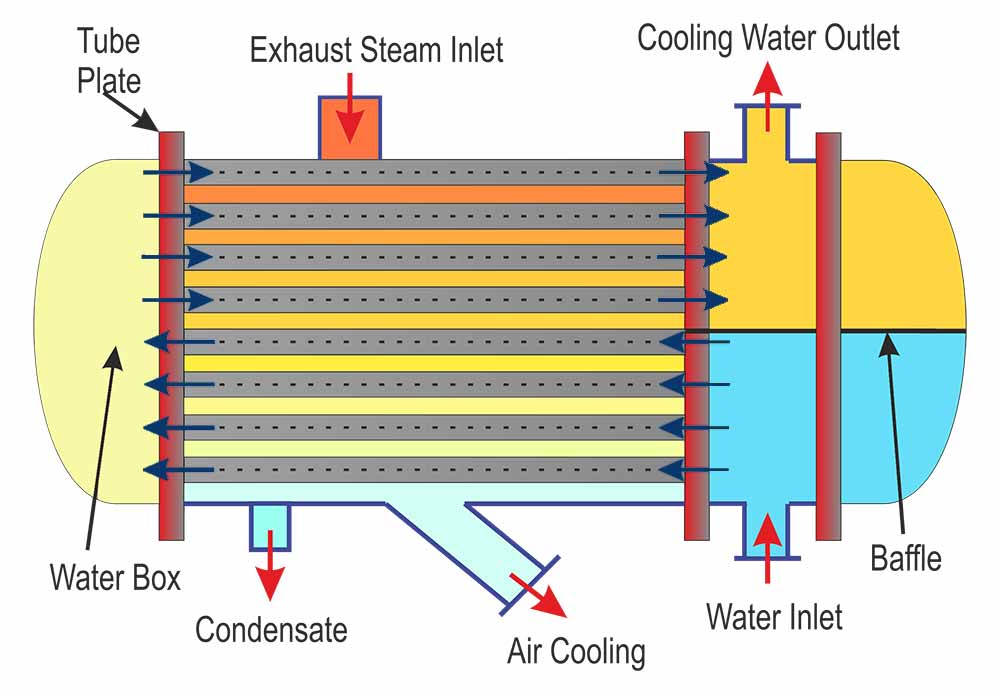

A surface condenser or steam condenser is a water-cooled shell and tube heat exchanger used to condensate the exhaust steam from the steam turbine in thermal power stations: the steam is converted from gaseous to liquid state at a pressure level below atmospheric pressure.

In steam surface condensers there is no mixing of exhaust steam and cooling water. The condensate can be re-used in the boiler: In surface condenser even impure water can be used for cooling purpose whereas in jet condensers cooling water must be pure. Although the capital cost and the space required is more in surface condensers but it is still preferred due to its low running cost and high thermal efficiency of plant.

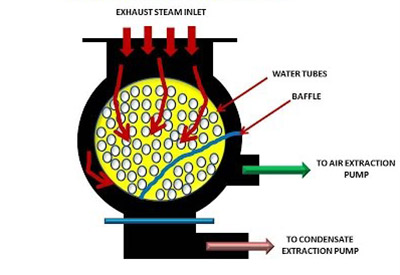

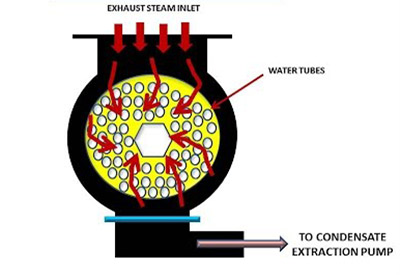

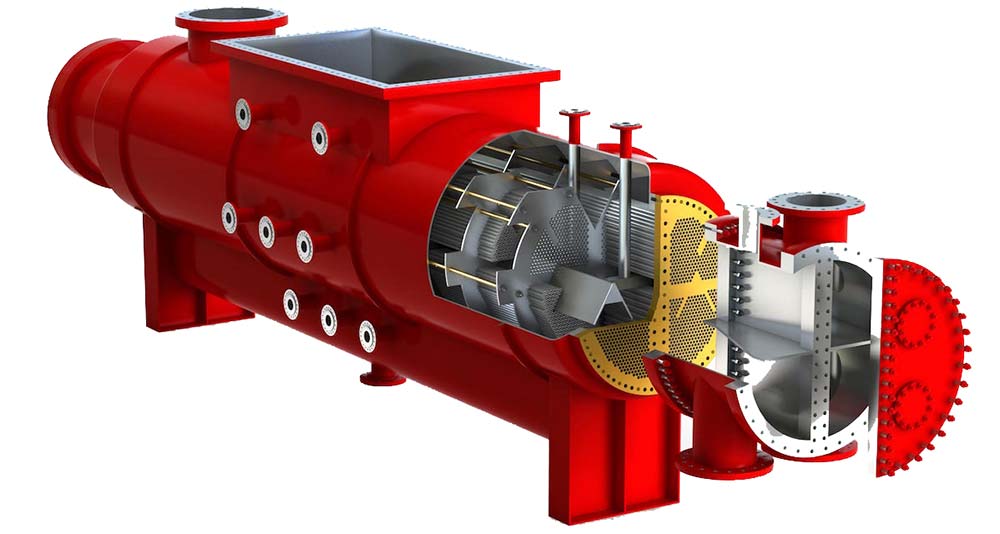

Surface condensers can be classified into varies types depending upon the position of condensate extraction pump, flow of condensate and arrangement of tubes.

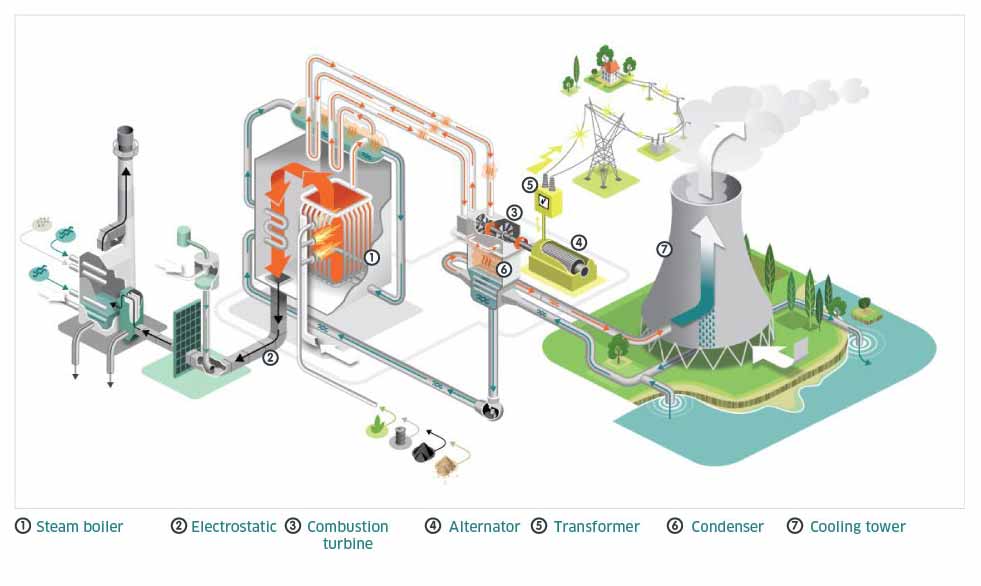

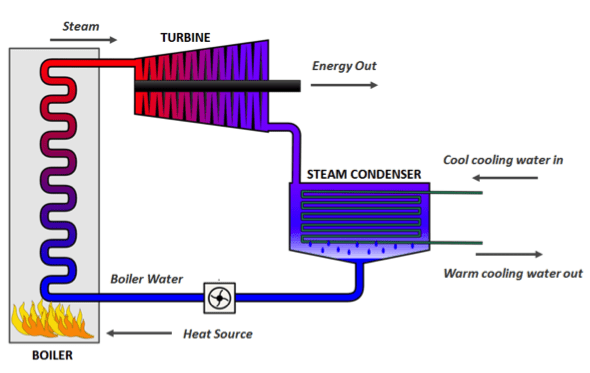

A thermal power station converts heat energy to electric power via steam-driven turbine: heated water turns into steam and drives a steam turbine connected to an electrical generator. After passing through the turbine, the steam is condensed in the condenser and recycled to the boiler for reheating and evaporation. This is the basic principle of the Rankine cycle.

The Rankine cycle operates in the following steps:

From the low-pressure turbine the exhaust steam enters the shell. The steam is cooled and converted to water (condensate) by flowing over the tubes of the condenser. Steam ejectors (or rotary motor-driven exhausts) continuously remove air and gases from the steam and while doing so maintain vacuum.

Lowest possible condenser temperatures achieve the lowest possible pressure in the condensing steam assures optimal efficiency. Since the condenser temperature can almost always be kept significantly below 100 °C where the vapor pressure of water is much less than atmospheric pressure, the condenser generally works under vacuum. Leakage of (non-condensible) air into the closed loop will decrease the vacuum, and therefore efficiency, and must be prevented.

Typically the cooling water causes the steam to condense at a temperature of about 25 °C (77 °F) and that creates an absolute pressure in the condenser of about 2–7 kPa (0.59–2.07 inHg), i.e. around −95 kPa (−28 inHg) below atmospheric pressure. The vacuum that is created through the large decrease in volume when water vapor condenses helps pull steam through the turbine for optimal efficiency.

Condenser generally use either circulating cooling water from a cooling tower to reject waste heat to the atmosphere, or once-through cooling surface water (from rivers, lakes or ocean). In many areas, cooling towers are mandatory even for once-through setups to avoid heating of the surface water and related biological impact.

Natural draft, forced draft or induced draft cooling towers reduce the temperature of the water by evaporation, by about 11 to 17 °C (20 to 30 °F) and dissipate non-recoverable waste heat to the atmosphere. A 500 MW unit will circulate around about 50,000 m³/hr (500 ft³/s or 225,000 US gal/min) at full load.

Condenser tubes are made of brass or stainless steel for optimal heat transfer and corrosion resistance. Bacteria, algae, mud or dust and scaling from the cooling water cause internal fouling and hinder heat transfer which leads to lower vacuum and therefore lower thermodynamic efficiency.

Efficient operation of thermal power plants is paramount to minimalize the cost (and carbon footprint) of electricity consumption. Carefully synchronized operation of the individual parts is required for this. With all technologies that were introduced to improve efficiency over recent decades, automatic condenser brushing may be the simplest solution that is often overlooked as an effective solution that may significantly increase the efficiency of power plant work.

Good steam condenser performance contribute a lot to total thermal power efficiency. As it was mentioned above, it allows to keep high condenser vacuum and avoid boiler tubes failures which results in high energy conversion.

For maintaining clean condenser tubes at all times consider the use of an automatic tube cleaning system like EQOBRUSH.

In automatic tube brushing we use a flow reversal valve to regularly (once every 4 hours) reverse the flow of cooling water over the condenser. This will then propel brushes (that are nestled in catch baskets at the end of each tube) through the tubes to remove any fouling from the tube walls. The fouling does not get the chance to settle in and start scaling and will sediment in the cooling tower basin.

Once the automatic tube brushing system is installed there is no more need to open the condenser for leaning. Reduction of downtime and the costs of maintenance are additional advantages to the output increase.

EQOBRUSH can be used for condensers with a diameter of the water in and outlet pipes of up to 600mm with our compact flow reversing valve. This means that we can fit our standard systems to steam turbine systems with an output of up to 40 MW per unit. This makes it ideal for biomass and smaller geo-thermal power plants. Larger condensers can be accommodated with specially engineered solutions.