- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

Range – the temperature difference between the hot water entering the cooling tower and the cold water exiting the cooling tower.

Approach – the difference between the cold cooling tower water and the Wet Bulb Temperature.

High cooling tower water temperature range – is a range of more than 12C in the cooling tower system.

Cooling towers normally handle a range of up to 12C, which poses a challenge for applications where a wider cooling tower water temperature range is required. Wacon’s thermal balancing basin concept has a proven track record in Europe and Asia and optimizes the operation for both footprint and Capex.

A cooling tower cascade with multiple cooling towers in a serial set-up is an obvious but sub-optimal solution for this challenge due to:

The greater footprint of the total cooling tower set-up, as 2 individual towers would need to be built for a serial (cascade) set-up

The over-sized total wet surface required, as each cooling tower needs a wet surface in the same range.

The primary cooling tower can be of a smaller size, as a relative large temperature drop can be achieved due to the high approach. The secondary cooling tower, which operates with a low approach, should be of a larger size. However, rain density limitations that need to be met to achieve performance do not allow for too much difference in wet surface size.

As a result of the above factors, the cascade approach will require a relative high investment per kW of cooling installed

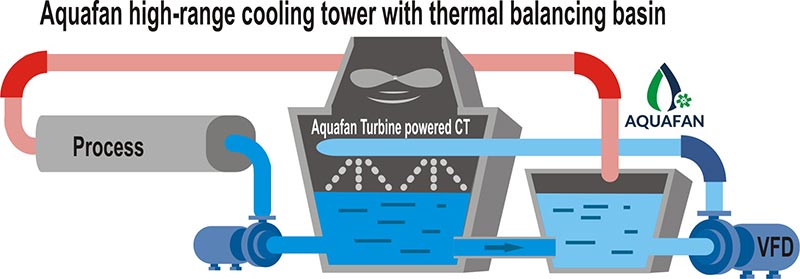

The thermal balancing basin in fact consists of 2 separated basins, each with different water temperatures, which are connected with a balancing pipe or opening in the separation wall. The balancing pipet makes the basins behave as communicating vessels. The cooling tower feeds into the cold basin, from which cold water is sent to the process. Hot water from the process is discharged into the warmer basin, which feeds the cooling tower.

Obviously, more water circulates over the cooling tower than over the process. This is required to expand the narrow cooling tower range to the wide process range. If the cooling tower water temperature range is 50% of the process range, the volume over the cooling tower is twice the process water volume.

As more water is drawn from the warm water basin, the cold cooling tower water is fed into the warm water basin via the balancing pipe. The effective temperature in the warm basin, therefore, is an outcome of the mixing of hot process water and cooling tower water. The cooling tower range is then the temperature difference between the mixed (warm) water basin and cooling tower cold water.

Wacon has applied this concept successfully in many challenging projects in both Europe and Asia, most recently in combination with the Aquafan cooling tower for further energy savings in operational cost. The pressure/volume from the VFD controlled cooling tower pump is regulated to maintain the required cold water temperature with minimal energy cost.

In a cement factory there is a cooling demand for 500m³ per hour

| Hot Water: | 55⁰C |

| Cold Water: | 35⁰C |

| Wet bulb temperature: | 29⁰C |

The cascade set-up:

| Cooling Tower unit | Range | Rain density | Wet Surface |

| 1 | 55-42⁰C | 18m³/m² x hr | 28 m² |

| 2 | 42-35⁰C | 23m³/m² x hr | 23 m² |

| Total | 55-35⁰C | N.A. | 51 m² |

Single unit set-up with balancing basin:

| Mixed Water Basin | 47.5⁰C | 500m³@55⁰C + 300m³@35⁰C = 800m³@47.5⁰C |

| Cooling Tower unit | Range | Rain density | Wet Surface |

| 1 unit @ 800 m³/hr | 47.5 -35⁰C | 18 m³/m² x hr | 44 m² |

| From Cooling Tower, 500 m³/hr to process and 300 m³/hr into balancing basin. | |||

The single unit saves 13% on wet surface = effective footprint.

On Capex (including installation cost) this option is 15-20% lower than the cascade approach.