- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

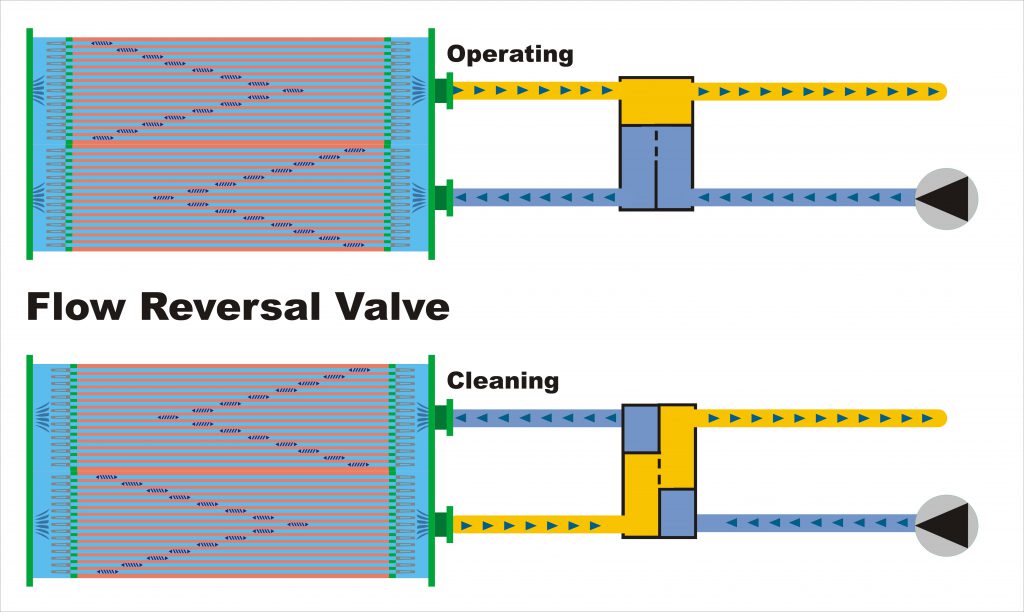

Back flushing heat exchangers is a systematic process to minimize fouling. Patented flow reversal valves offer an intelligent solution, ensuring minimal pressure loss and installation impact. Standard 2, 3, or 4-way valves present a cost-effective alternative for those prioritizing initial investment over long-term operational expenses. Explore these strategies further below.

Since the back flushing of heat exchangers takes place during operation, the cost of manpower, cleaning equipment, and standstill or production losses are minimized. Also, it extends the interval between cleaning sessions.

In plate heat exchangers, back-flushing washes away debris stuck at the cooling water inlet of the unit. For shell and tube heat exchangers, the back-flush works best in combination with brushes that travel through the tubes in response to the reversed flow. They nestle in catch baskets, designed for minimal flow restrictions, at the end of each tube during normal operation.

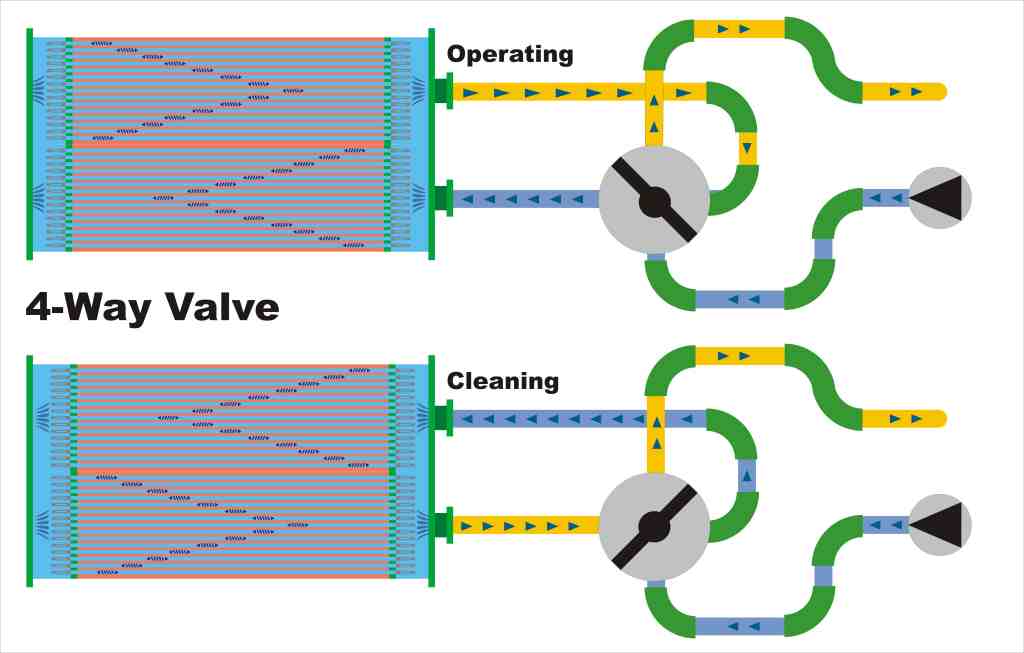

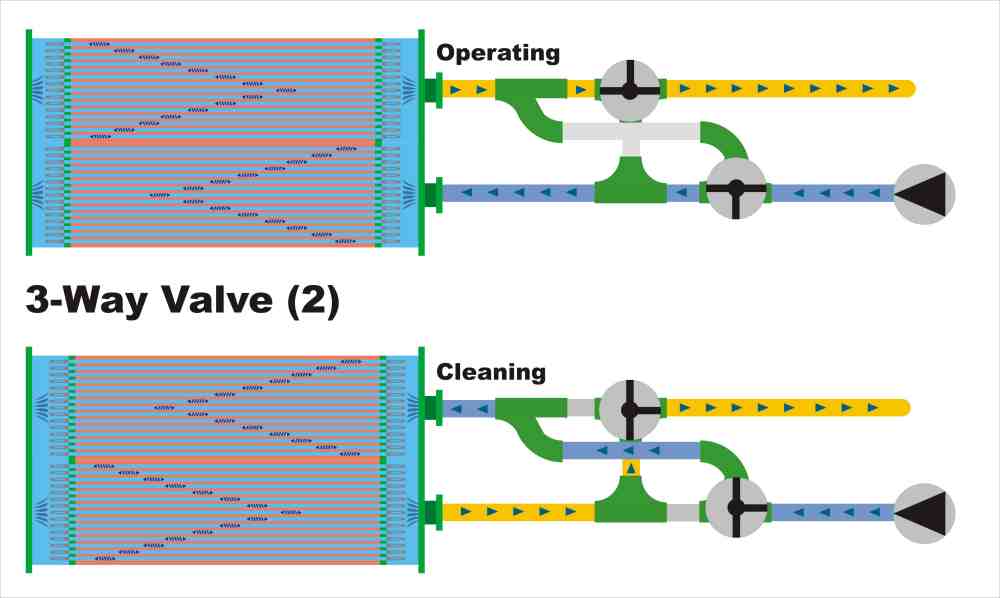

Here we present various methods for accomplishing back flushing heat exchangers: reversing the flow over the heat exchanger without altering the flow direction to the cooling tower. Each approach offers distinct advantages and disadvantages in terms of practical implementation, technical complexity, and associated costs.

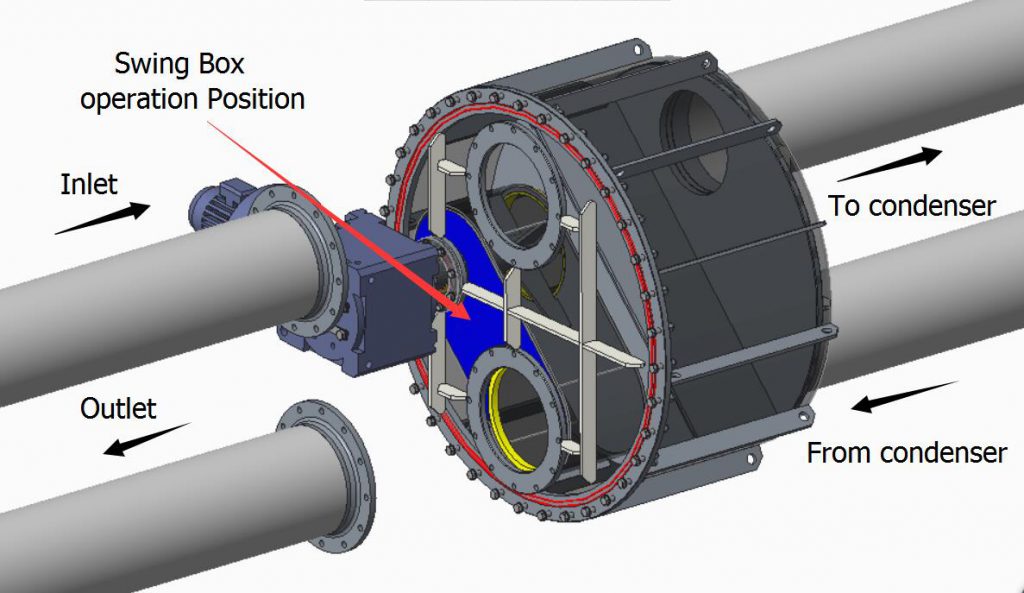

Our preferred solution is the patented and compact Eqobrush Swingbox Flow Reversal Valve. While it requires a slightly higher initial investment (CAPEX), it offers years of trouble-free operation with minimal pressure loss and cold water crossover into the warm water stream.

This Flow Reversal Valve is engineered for minimal pressure loss, occurring solely during the system’s cleaning cycle, totaling approximately 5 minutes per 24 hours of operation.

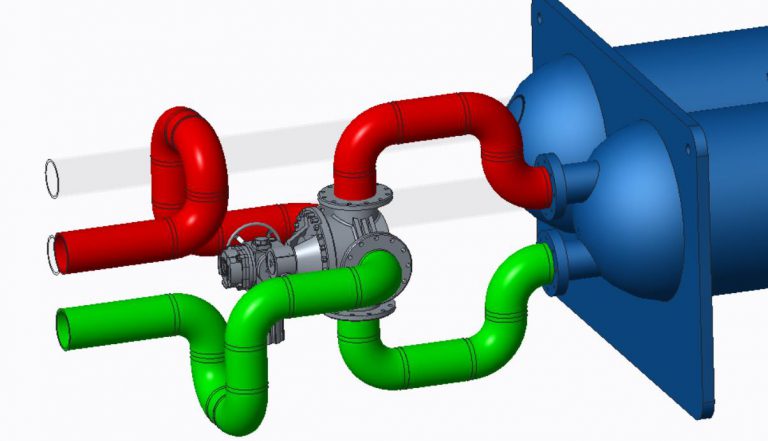

The 4-way valve presents challenges in fitting into piping solutions due to its shape, leading to increased footprint and installation complexities. Moreover, it poses operational expenditure (OPEX) issues, including constant pressure loss due to piping elbows. While it offers limited capital expenditure (CAPEX) advantages compared to Flow Reversal Valves, its drawbacks may outweigh the cost benefits.

Our preference for 4-way valves is primarily for projects with small pipe diameters, where the CAPEX advantage is most pronounced. In such scenarios, the cost benefit of 4-way valves outweighs their installation complexities and operational considerations.

Synchronizing a set of 3-Way valves is essential for the back flushing heat exchangers process to reverse flow without water stagnating for extended periods. However, this setup poses control challenges, as a single defective actuator can lead to system failure. Additionally, it results in a footprint increase and requires higher capital expenditure due to the necessity of two actuators of equal power.

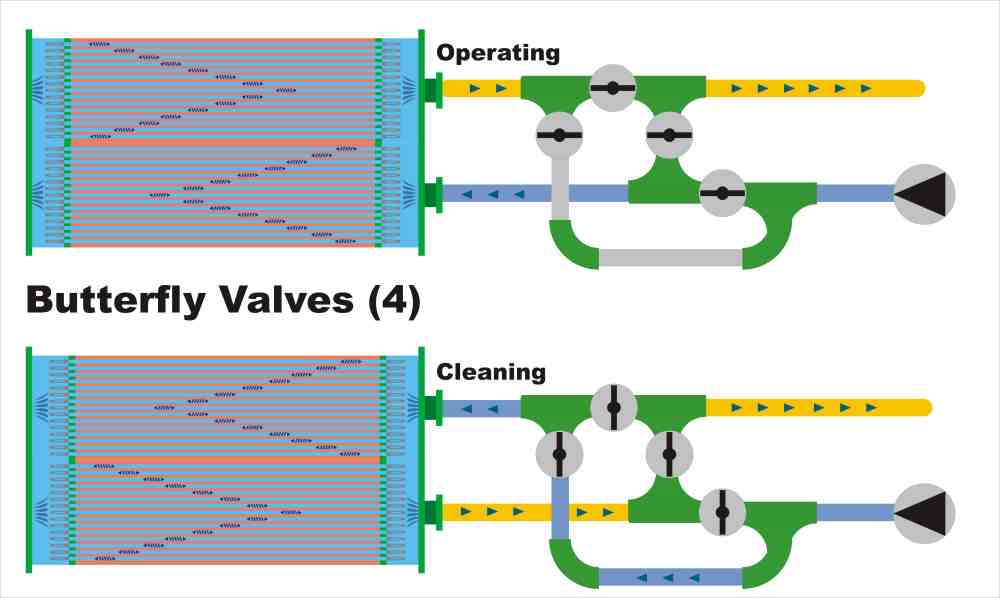

Synchronizing 4 butterfly valves is crucial for reversing flow during the back flushing heat exchangers, preventing water from stagnating for too long. However, this setup presents control challenges, as a single defective actuator can cause system failure. Moreover, it increases the footprint and requires higher capital expenditure due to the need for four actuators of equal power.

The forces acting within valves correspond directly to the water volumes within pipes, increasing in proportion to the diameter squared at a constant water speed. Such forces impose constraints on the use of complex valves like the Eqobrush swing box flow reversal valve. Additionally, practical considerations limit the valve body width, making diameters exceeding 600 mm impractical for cooling tower to heat exchanger or condenser pipes.

Obviously, when applying a solution that involves 2 or 4 valves, the coordination and synchronization become an issue. The process management system should provide precautions to avoid the water flow coming to a halt or the heat exchanger from being bypassed for an extended period.

The above schematic drawings make it clear that more valves require a complex pipe layout. The practical aspects of this in terms of available space as well as the cost of installation may prove burdensome, not in the least in the case of retrofitting existing installations.

Simpler solutions cause lower pressure loss. Complex pipework means more pressure loss, subsequently the energy consumption of the system pump increases. This particularly applies to the 4-way valve.

Old fashioned flow reversal valves and standard of the shelf 2-3 or 4-way valves may come with the defect of substantial cross-over: the leaking of cool water (from the cooling tower) into the return hot water stream. This basically reduces cooling tower capacity, as the less cool water reaches the process. In practice, up to 5% of the capacity may be lost via cross-over.

Simple valve solutions can be cheaper in material investment. However, this may be countered by cost of installation and the cost of the process management system.

In critical processes where significant gains are at stake, opting for inexpensive solutions may lead to short-term benefits but long-term drawbacks. We advocate for thoughtful consideration of the optimal solution, prioritizing return on investment (ROI) and ensuring worry-free operations over an extended period.

Reading tip on backflushing of heat exchangers:

HPAC-magazine (Heat Plumbing and Air Conditioning): Changing Flow Direction for Optimal Heat Exchanger Performance

Chemical Processing: Backflush Away Fouling

The complexity of fitting a 4-way valve into the piping configuration is evident. Each angle introduces additional pressure loss, necessitating compensation through increased pump power. This added complexity underscores the importance of careful consideration when selecting valve types to optimize system efficiency and performance.

Discuss your project needs with us to assist in selecting the right equipment and conducting an ROI assessment. Get budget quotations for condenser cleaning using Eqobrush technology. Let’s collaborate to optimize your project with the ideal solutions tailored to your requirements.