- Main

- Chiller Efficiency

- Auto Tube Brushing

- Cooling towers

- Motorless Turbine

- Contact Us

Advantages of AQUAFAN are impressive. Low energy and noise. It’s made of portable units, uses modular cooling tower system and is safe in EEx. Aquafan turbine powered Cooling Towers convert water pressure into fan movement. The Aquafan cells are controlled via the system pump that generates sufficient pressure to drive the fan. It’s simple and efficient.

The AQUAFAN cooling tower is made flexible in capacity and construction by applying a modular cooling tower system. Extension of existing cooling towers is possible by simply adding modules.

The AQUAFAN B6A cooling tower is designed for an axial fan with a diameter of 1.8 m. This diameter is standard for each module. The basic module size can vary from 2.4*2.4 (8’ x 8’) to 3.6*3.6 (12’x12’) m. Configurations like B6A8, B6A10 or B6A12 are possible.

So, obvious advantages of AQUAFAN cooling towers is that they can be installed for every required cooling capacity. Depending on its capacity, the floor surface or footprint varies from 5,76 m2 (64 sqft) to a few hundred (10000 sqft) m2.

The capacity/surface ratio in AQUAFAN is comparable to conventional cooling towers.

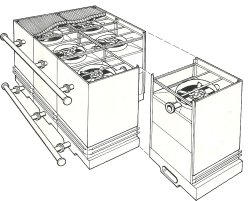

The AQUAFAN cooling tower illustrated opposite in a 3 x 2 set up, is designed in pre-fabricated modular cooling tower construction. The total surface for these six modules in a B6A10 configuration is 6.0* 9.0 meters.

The portable cooling tower units come pre-assembled and are suitable for temporarily cooling jobs where a quick set-up is a requirement. Units can be shipped in regular sea containers. Once on site they only need to be connected to the system pump and are ready to operate. Check pump requirements with your account manager.

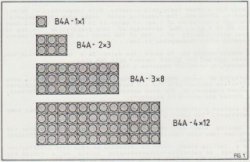

Sizes:

AQUAFAN Cooling Tower Repair and Maintenance is very easy. Motors, Gearboxes and Drive Shafts, which account for 95% of the operational problems, are absent in AQUAFAN cooling towers. The only moving part, the fan/turbine assembly, runs on a set of graphite impregnated Teflon bearing rings on a stainless steel sleeve. Lubrication is achieved through a constant supply of cooling water. Inspection or replacement of the bearing rings can be done simply by unscrewing the cover plate and removing the whole turbine set. When more than one module is being used, this can even be done in as little as 10 minutes by switching off the cell to be inspected and eliminating the need shut down the entire cooling tower process. The AQUAFAN cooling tower requires minimal maintenance.

Using a modular system in the larger capacities greatly simplifies the use of spare parts. The only parts you need to have on stock are a set of bearing rings. The general lifetime of the bearings depends on the operated water quality and is between 1 and 3 years. Routine maintenance of the AQUAFAN cooling tower is hardly necessary. It is recommended to inspect the complete condition of the turbine, the bearings, the drift eliminators and the packing 4 times annually. The AQUAFAN cooling tower is accessible from the top, to allow removal, picking up and moving aside the drift eliminators. The turbine is also easy to access in this way.

Cooling towers with electric drives should be lubricated and inspected regularly at various points. The circulating cooling water lubrication of an AQUAFAN cooling tower is achieved automatically. This system has proved itself during more than 25 years in numerous operating modules and to the full satisfaction of their users.

Another advantage is the choice of material for the turbine/fan unit, namely ABS plastic and stainless steel. Corrosion is excluded here. The other parts of the cooling tower are likewise designed from corrosion resistant materials. Certainly, by using light fans with a small diameter and low speed, there is no damage in the event of one of the fan blades breaking. The damage that can occur with the use of heavy motors and/or large fans is impossible with the AQUAFAN cooling tower.

The turbine design creates an even distribution of water droplets eliminating the need for nozzle dispersion of water.

AQUAFAN is a low energy consumption cooling tower. The cooling tower is the only one item in a cooling water system. The cooling water pumps and fans take care of water and air circulation and, consume energy by doing so. A cooling tower is designed to give maximum capacity at a given maximum ambient temperature (WBT wet bulb temperature). However, this wet bulb temperature is not reached for a great part of the year.

Excess cooling tower capacity is reduced in an economical manner to the actual outside conditions. The speed of the water turbine is proportionally controlled by the volume and pressure of the cooling water. Adjustment can thus be made to variations in ambient temperatures or process requirements.

The tower capacity is totally controlled by the surrounding conditions. In low season only a part of the flow needs to be operated to enhance a stable output temperature, whilst in peak times the full flow is available. The water energy is controlled by a multi-pump system or a frequency controlled pump system.

In situations where the cooling demand is around 75% of the design conditions, AQUAFAN cooling towers use 50% less energy compared to conventional cooling tower systems.

Due to the elimination of an electric motor and the speed of the low weight fan/turbine assembly the noise level of the AQUAFAN cooling tower is very low. Positioning the drift eliminators above the fan/turbine assembly is responsible for an even further reduced noise level. The Noise power Level (SPL) of one unit at the maximum operational level does not exceed 80 +/-2 dB(A). Within 10 meter/yard of the tower it is 58 dB(A).

Typical winter-time problems with cooling installations such as freezing of packing and fan blades are caused by too much air over the cooling tower. The proportional control of water and air is the solution to these difficulties.

Freezing up of the fan during a standstill period is no problem, as the warm cooling water at start-up will thaw the fan/turbine assembly.

Running your cooling system with a constant cold water temperature during winter is possible with the AQUAFAN cooling tower.

AQUAFAN cooling towers are the best choice for applications in Explosion Proof environments (EEx).

Simply because there is no wiring or electrical equipment at the cooling tower. AQUAFAN is made of explosion proof portable units and fan.

As you could see the advantages of AQUAFAN are really impressive. It has low energy consumption, low noise and requires low maintenance. It’s easy to be transported and assembled. It’s suitable for explosion proof environment and cold weather conditions. It’s simple and efficient. Learn more about the concept used in its design and feel free to contact us for additional information.