水流流向切换对抑制各种换热器结垢累积形成是一种极其有效的办法,流向切换可以通过使用一种智能的,专利设计换向阀实现,该换向阀同时具有最低压力损失,接近零的交叉率以及十分紧凑的特点。或者,考虑到较低的成本支出(高成本运行)因素可以选择2个,3个以及4个阀门组合使用。对于不同的几个方案,以下请看以下内容:

水流流向切换对抑制各种换热器结垢累积形成是一种极其有效的办法,流向切换可以通过使用一种智能的,专利设计换向阀实现,该换向阀同时具有最低压力损失,接近零的交叉率以及十分紧凑的特点。或者,考虑到较低的成本支出(高成本运行)因素可以选择2个,3个以及4个阀门组合使用。对于不同的几个方案,以下请看以下内容:

对各种类型的换热进行有规律的反冲洗可以降低污垢的生成。水流逆向切换可以通过使用一种智能的,专利设计换向阀实现,该换向阀同时具有最低压力损失,接近零的交叉率以及十分紧凑的特点。或者,考虑到较低的设备成本支出(高成本运行)因素可以选择2个,3个以及4个阀门组合使用。对于不同的几个方案,请看以下内容:

由于反冲洗的动作是在换热器工作过程中进行的,因此,可以降低人工成本的支付,减少清洗设备的投入,以及降低停机机会及其造成的生产损失。而且反冲洗还能大大延长全面清洗的间隔。

在板式换热器上,反冲洗可有效冲走设备冷却水进水口的积聚污物。对于壳管式换热器而言,反冲洗设备配上刷子就是最佳的选择,刷子随着水流的换向来回穿梭于管束两端,刷子在不工作的状态下会驻留在管端的捕捉篮内,其特殊而巧妙的设计对水流不会造成任何影响。

接着下来,我们介绍几种可实现反冲洗的办法:不影响流向冷却塔水流方向,只切换流向换热器的流向。每一个方案都会具体涉及到实际运行中各自的优缺点,技术实现的复杂性以及相关的成本。

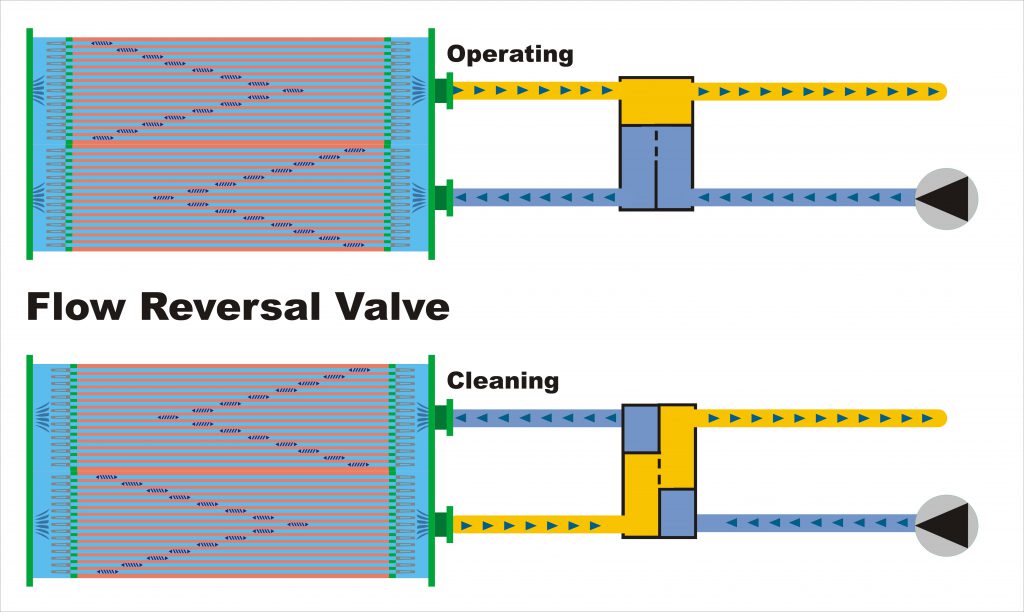

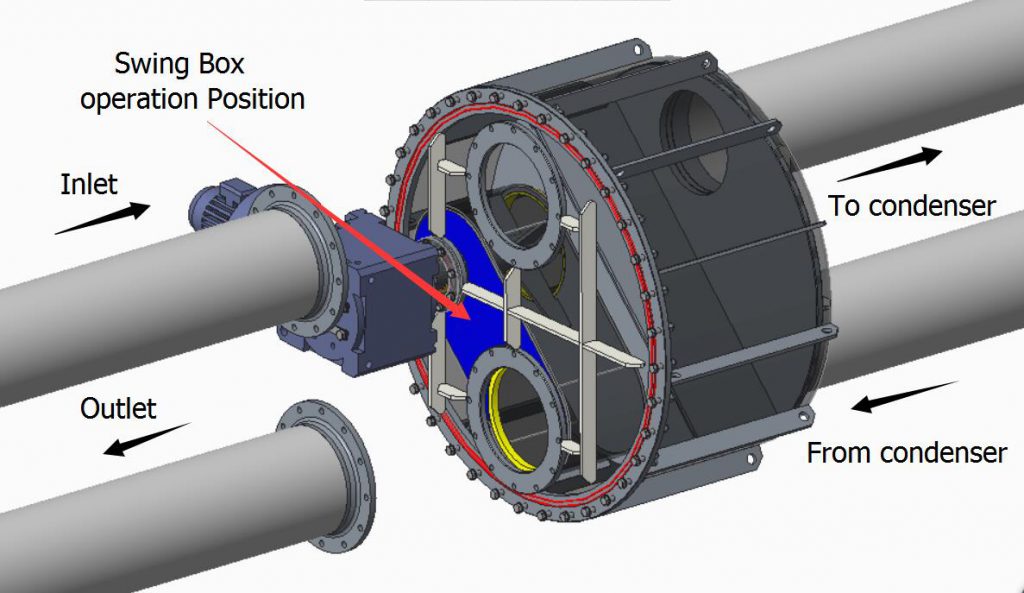

我们推荐的方案:Eqobrush专利设计的摆箱式换向阀,稍高的投资(CAPEX)可以在多年的无忧运行中实现回报,同时将压力损失降低,冷水交叉到热水流中能实现最低的涉漏率。

压力损失只发生在清洗周期内,24小时内所有清洗周期所需要的时间仅仅为5分钟。

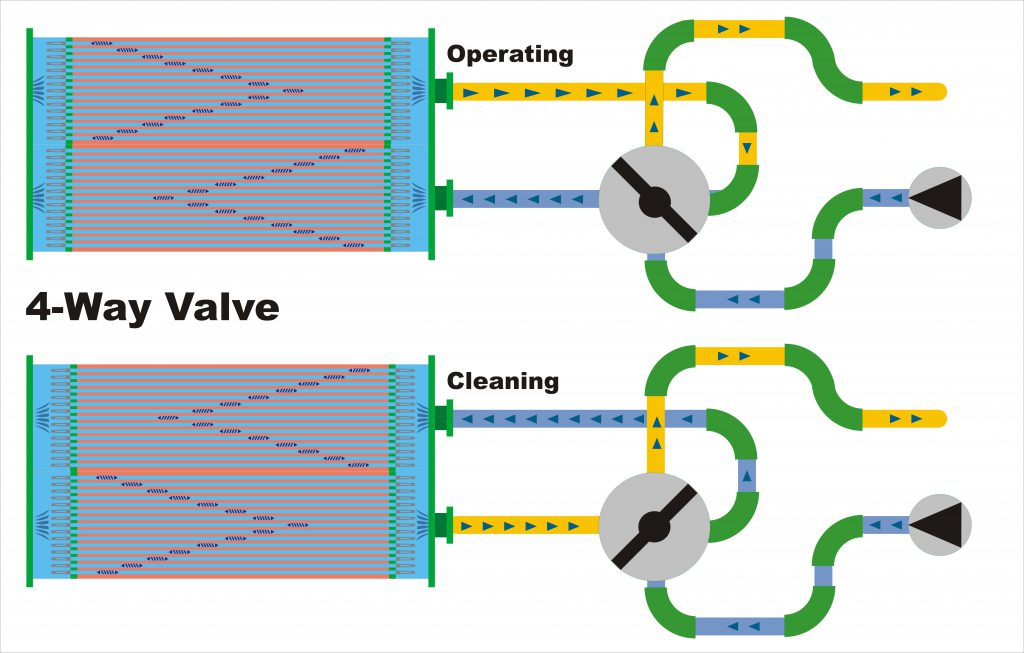

4通阀 因其造型问题很难适配装置到管网解决方案中。

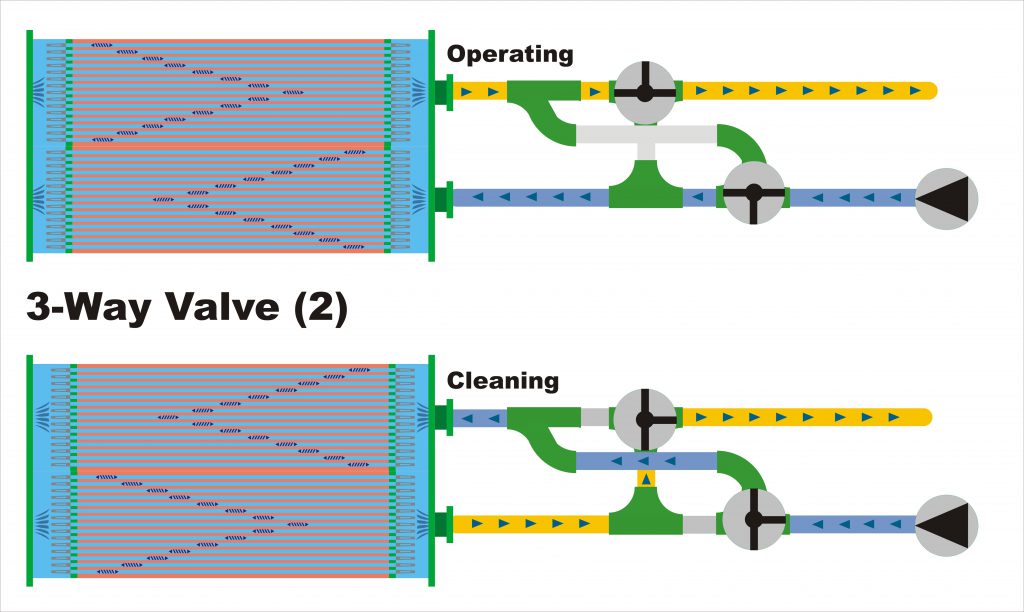

这套3通阀需要与水流逆向同步,并且要求逆向水流不能在长时间内作停留。

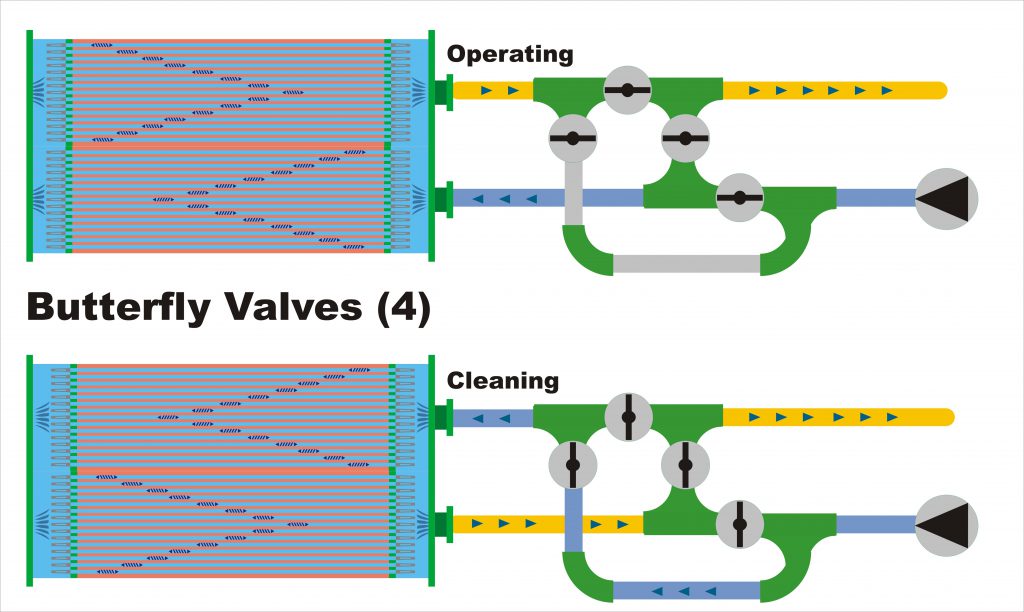

蝶阀也一样需要与水流逆向同步,并且要求逆向水流不能在长时间内作停留。

The forces applicable within the valves are directly proportional to the water volumes flowing through the pipes. They are expressed as a square function of the pipe diameter, based on constant water speed. These forces limit the application of the complex valves, such as the Eqobrush swing box flow reversal valve.

Also, the width of the valve body will, above certain pipe diameters, no longer be practical to consider. The practical limitation is set to a (cooling tower to heat exchanger or condenser) pipe diameter of 600 mm.

Obviously, when applying a solution that involves 2 or 4 valves, the coordination and synchronization become an issue. The process management system should provide precautions to avoid the water flow coming to a halt or the heat exchanger from being bypassed for an extended period.

The above schematic drawings make it clear that more valves require a complex pipe layout. The practical aspects of this in terms of available space as well as the cost of installation may prove burdensome, not in the least in the case of retrofitting existing installations.

Simpler solutions cause lower pressure loss. Complex pipework means more pressure loss, subsequently the energy consumption of the system pump increases. This particularly applies to the 4-way valve.

Old fashioned flow reversal valves and standard of the shelf 2-3 or 4-way valves may come with the defect of substantial cross-over: the leaking of cool water (from the cooling tower) into the return hot water stream. This basically reduces cooling tower capacity, as the less cool water reaches the process. In practice, up to 5% of the capacity may be lost via cross-over.

Simple valve solutions can be cheaper in material investment. However, this may be countered by cost of installation and the cost of the process management system.

对于那些能够获得大量效益的关键流程上,“短期获益,长期痛苦”的原则只适用一些廉价的解决方案。我们建议在长期投资回报率(ROI)和无忧操作方面仔细考虑最佳解决方案。

有关反冲洗换热器的阅读提示:

https://www.chemicalprocessing.com/articles/2012/backflush-away-fouling/

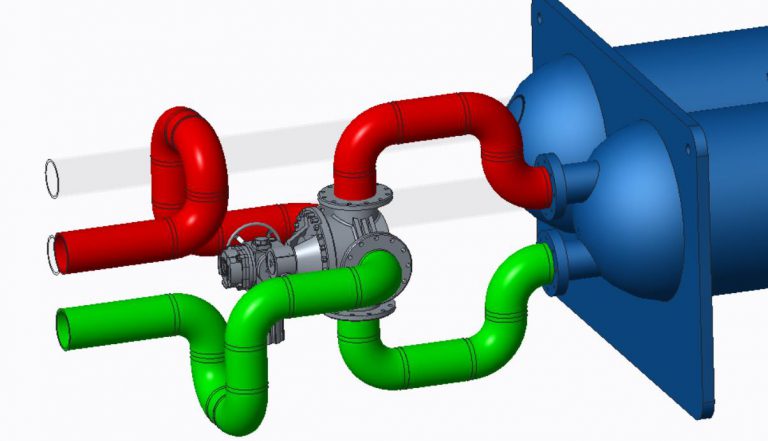

所看到的是,将4通阀安装到管道配置中的复杂性。 每个角度都涉及额外的压力损失,而且都是需要通过泵功率进行补偿的。